This conversion use a LED base lamp, it is configured with two easy LED modules stick on both sides of driver, This is a 32 watt LED base lamp with diffusers. One of good application for this base lamp is to be a LED replacement luminaries for torchiere lamp; It's very bright yet only use 32 watts. Not just energy, I did this also because the CFL bulbs used in lamp were making too much noise for reading.

The kit comes as 2 diffusers, pre-wired 2 bent LED module and one driver.

(1) first install diffusers on to the modules.

(2) peel off the double sided tape and fasten LED modules to two sides of driver, with light output point outward.

This is our LED light Gut, about 9" long, 4" tall and 5.5" wide, weight just 1.0 lb

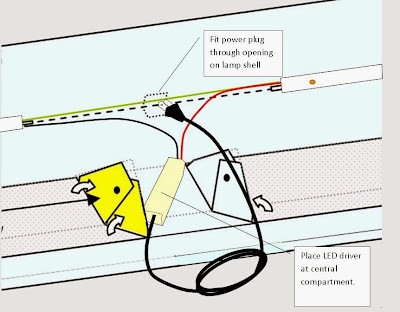

(3) Work on the torchiere Lamp, clean existing light gut that is either using light bulb or Halogen; only leave AC power wires

The metal plate can be bent using a pair of pliers for fitting in the bowl.

Adjust module inside Lamp shell so it can point light to where we need it most. See how bright it make a room.